Filters

Finishing Pads

-

Translation missing: en.product_price.item.price.range_htmlOriginal pricefrom £6.00from £6.00Current price £6.00| /

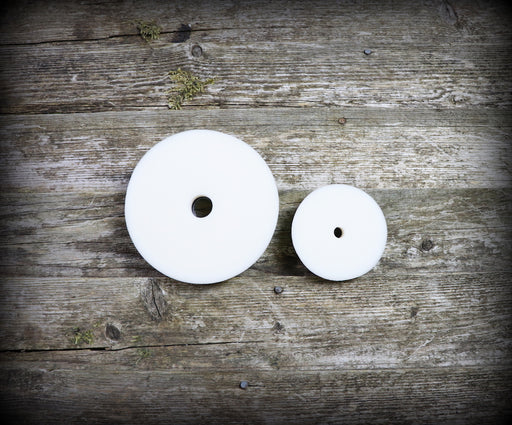

CARPRO White Gloss Pad

The CARPRO Gloss Pad is made of a unique Japanese open cell polyurethane foam specifically designed for finishing to a high gloss on many paint typ...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal pricefrom £6.00from £6.00Current price £6.00| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£14.99from £14.99Current price £14.99| /

Chemical Guys Black Hex Logic Quantum Extra Soft Finishing Pad

Black Quantum Pads are extra light duty finishing pads. While cutting and polishing pads remove paint to restore gloss and shine, finishing pads ha...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£14.99from £14.99Current price £14.99| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£12.98from £12.98Current price £12.98| /

Chemical Guys Black Hex Logic Extra Soft Finishing Pad

Chemical Guys Black Hex Logic Extra Soft Finishing Pad is firm enough to withstand added pressure during final finishing to remove buffer swirls. I...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£12.98from £12.98Current price £12.98| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£26.09from £26.09Current price £26.09| /

Meguiar's 5" DA Microfibre Finishing Pad (Pack of 2)

Meguiar's DA microfiber system is a brand new development in correction using a dual action polisher. When these pads were introduced they really c...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£26.09from £26.09Current price £26.09| / -

Original price £12.98Translation missing: en.product_price.item.price.range_htmlOriginal price £12.98Current price £9.60from £9.60Current price £9.60| /

Chemical Guys Blue Hex Logic Soft Finishing Pad (5.5")

Chemical Guys Blue Hex Logic Soft Finishing Pad delivers a super fine finish for use with ultra fine polishes, glazes and light surface cleaners. H...

View full detailsOriginal price £12.98Translation missing: en.product_price.item.price.range_htmlOriginal price £12.98Current price £9.60from £9.60Current price £9.60| /Save 26% Save % -

Translation missing: en.product_price.item.price.range_htmlOriginal price£5.21from £5.21Current price £5.21| /

Flexipads 3" DA Microfibre Cutting Disc

Flexipad foam yellow finishing disc, for use with a DA polishing machine. Microfibre surface with a 10mm foam layer. The microfibre disc technology...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£5.21from £5.21Current price £5.21| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£27.83from £27.83Current price £27.83| /

Meguiar's 6" DA Microfibre Finishing Discs (Pack of 2)

New microfiber disc technology refines surface to a high gloss finish. Engineered foam interface for optimal cutting efficiency, and controlled con...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£27.83from £27.83Current price £27.83| / -

Translation missing: en.product_price.item.price.range_htmlOriginal pricefrom £20.34from £20.34Current price £20.34| /

3M Black Perfect-It III High Gloss Pad (150mm)

Long lasting waffle foam Easily attached to 3M back-up pads Helps to deliver a high gloss finish. Removes compounding swirl marks, perfect for dark...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal pricefrom £20.34from £20.34Current price £20.34| / -

Translation missing: en.product_price.item.price.range_htmlOriginal pricefrom £7.04from £7.04Current price £7.04| /

Koch-Chemie One Cut Foam Pad

The brand new Koch-Chemie One Cut Pad is made from medium abrasive sponge designed to remove moderate weathering and deep scratches working in coll...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal pricefrom £7.04from £7.04Current price £7.04| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£9.22from £9.22Current price £9.22| /

Lake Country Green Foam Polishing / Finishing Pad (5.5 Inch)

The Lake Country Green Foam Polishing / Finishing Pad is designed for use with polishes, light swirl removers, and one-step cleaner waxes. This pad...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£9.22from £9.22Current price £9.22| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£5.69from £5.69Current price £5.69| /

Flexipads Yellow X-Slim Finishing Pad (5.5")

Do you need help with optimising your automobiles polishing potential? With Flexipads Yellow X-Slim Finishing Pad, you can achieve just this. Featu...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£5.69from £5.69Current price £5.69| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£9.18from £9.18Current price £9.18| /

Lake Country Black Foam Finessing Pad

The Lake Country Black Foam Finessing Pad is designed to apply glazes, finishing polish, and sealants without absorbing too much of the product. Th...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£9.18from £9.18Current price £9.18| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£9.32from £9.32Current price £9.32| /

Flexipads Red Pro-Detail Ultra Fine Finishing Pad (5.5")

Flexipads Red Pro-Detail Ultra Fine Finishing Pad delivers a premium-quality, super fine finish for use with wax and sealant products. Featuring a ...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£9.32from £9.32Current price £9.32| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£9.66from £9.66Current price £9.66| /

Lake Country Red Foam Final Finishing Pad

The Lake Country Red Foam Final Finishing Pad is designed for use with light polishes, waxes, and sealants. This pad is very soft and is designed f...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£9.66from £9.66Current price £9.66| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£9.32from £9.32Current price £9.32| /

Flexipads Black Pro-Detail Finishing Pad (5.5")

Flexipads Black Pro-Detail Finishing Pad (5.5") is a hexagonal-shaped finishing pad designed to both retain compound and achieve an exceptionally e...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£9.32from £9.32Current price £9.32| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£5.80from £5.80Current price £5.80| /

Flexipads 3" DA Microfibre Finishing Disc

Flexipad foam black finishing disc, for use with a DA polishing machine. Microfibre surface with a 10mm foam layer. The microfiber disc technology ...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£5.80from £5.80Current price £5.80| / -

Translation missing: en.product_price.item.price.range_htmlOriginal pricefrom £11.03from £11.03Current price £11.03| /

Koch-Chemie Polish & Sealing Foam Pad

The brand new Koch-Chemie Polishing & Sealing Pad is made from extra-fine finish sponge designed to economically and evenly apply sealing produ...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal pricefrom £11.03from £11.03Current price £11.03| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£14.88from £14.88Current price £14.88| /

Lake Country HDO Foam Cutting Pad (Black)

The Black Lake Country HDO Pad is a finishing pad designed to remove light holograms and hazing whilst leaving a high gloss finish. Lake Country HD...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£14.88from £14.88Current price £14.88| / -

Original price £26.40Translation missing: en.product_price.item.price.range_htmlOriginal price £26.40Current price £12.00from £12.00Current price £12.00| /

Koch-Chemie Green Polishing & Sealing Foam (45x23mm)

The Koch-Chemie Polishing & Sealing Pad is made from extra fine sponge designed to economically and evenly apply sealing products such as Koch-...

View full detailsOriginal price £26.40Translation missing: en.product_price.item.price.range_htmlOriginal price £26.40Current price £12.00from £12.00Current price £12.00| /Save 55% Save % -

Translation missing: en.product_price.item.price.range_htmlOriginal price£32.99from £32.99Current price £32.99| /

3M Perfect-It 1-Step Foam Finishing Pad 150mm (Pack of 2)

3M Pack 2 150mm Perfect-it III purple foam pads, designed for use with 3M Perfect-it Famous Finish. Used in conjunction with Trizact 3000 and 8000 ...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£32.99from £32.99Current price £32.99| / -

Original price £14.99Translation missing: en.product_price.item.price.range_htmlOriginal price £14.99Current price £10.50from £10.50Current price £10.50| /

Chemical Guys Blue Hex Logic Quantum Light Finishing Pad (5.5 Inch)

Chemical Guys Blue Hex Logic Quantum Light Finishing Pads are light duty finishing pads. Cutting and polishing pads remove paint to restore gloss a...

View full detailsOriginal price £14.99Translation missing: en.product_price.item.price.range_htmlOriginal price £14.99Current price £10.50from £10.50Current price £10.50| /Save 30% Save % -

Translation missing: en.product_price.item.price.range_htmlOriginal price£6.32from £6.32Current price £6.32| /

3M Finesse-It Foam Buffing Pad (Red, 80mm)

The 3M Finesse-It Buffing Pad - Red Foam removes the abrasive sand scratches that were created to remove small defects in automotive clear coats. Y...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£6.32from £6.32Current price £6.32| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£6.32from £6.32Current price £6.32| /

3M Finesse-It Foam Buffing Pad (Charcoal, 80mm)

The 3M Finesse-It Buffing Pad - Charcoal Foam removes the abrasive sand scratches that were created to remove small defects in automotive clear coa...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£6.32from £6.32Current price £6.32| / -

Translation missing: en.product_price.item.price.range_htmlOriginal price£27.19from £27.19Current price £27.19| /

Koch-Chemie Orange One Cut Foam 5pk (45mm)

The brand new Koch-Chemie One Cut Pad is made from medium abrasive sponge designed to remove moderate weathering and deep scratches working in coll...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£27.19from £27.19Current price £27.19| / -

Original price £12.24Translation missing: en.product_price.item.price.range_htmlOriginal price £12.24Current price £8.50from £8.50Current price £8.50| /

Malco Epic Black Foam Finishing Pad (5.5 Inch)

Hook and loop pad designed to work alongside Epic Finishing Polish. It has small, open cells that allow the polish to remain close to the surface. ...

View full detailsOriginal price £12.24Translation missing: en.product_price.item.price.range_htmlOriginal price £12.24Current price £8.50from £8.50Current price £8.50| /Save 31% Save % -

Original price £43.26Translation missing: en.product_price.item.price.range_htmlOriginal price £43.26Current price £26.40from £26.40Current price £26.40| /

Flex Polishing Sponge - Two Pads (Black)

The Black Flex Polishing Sponge has a soft foam texture for finishing to a deep sheen. Its special reticulation makes this foam tear-resistant and ...

View full detailsOriginal price £43.26Translation missing: en.product_price.item.price.range_htmlOriginal price £43.26Current price £26.40from £26.40Current price £26.40| /Save 39% Save % -

Translation missing: en.product_price.item.price.range_htmlOriginal price£27.19from £27.19Current price £27.19| /

Koch-Chemie Green Polishing & Sealing Foam 5pk (45x23mm)

The brand new Koch-Chemie Polishing & Sealing Pad is made from extra-fine finish sponge designed to economically and evenly apply sealing produ...

View full detailsTranslation missing: en.product_price.item.price.range_htmlOriginal price£27.19from £27.19Current price £27.19| / -

Original price £7.58Translation missing: en.product_price.item.price.range_htmlOriginal price £7.58Current price £5.40from £5.40Current price £5.40| /

Flexipads Yellow X-Slim Finishing Pad (6.5")

Do you need help with optimising your automobiles polishing potential? With Flexipads Yellow X-Slim Finishing Pad, you can achieve just this. Featu...

View full detailsOriginal price £7.58Translation missing: en.product_price.item.price.range_htmlOriginal price £7.58Current price £5.40from £5.40Current price £5.40| /Save 29% Save % -

Original price £10.00Translation missing: en.product_price.item.price.range_htmlOriginal price £10.00Current price £7.20from £7.20Current price £7.20| /

Scholl NEO Spider Puck Applicator (Honey, 130mm)

The Scholl NEO Spider Puck is a calibrated puck made of fine, tear-resistant foam. Ideal for an even, deep-down application of NEO polymer paint pr...

View full detailsOriginal price £10.00Translation missing: en.product_price.item.price.range_htmlOriginal price £10.00Current price £7.20from £7.20Current price £7.20| /Save 28% Save %

Polishing pads are designed to be used in conjunction with a machine polisher in order to apply liquid compound to a surface. When machine polishing your paintwork, choosing the right car polishing pads is key. The stiffness of a foam polishing pad will have a different effect on the paintwork surface, the heavier the cut, the more abrasive the pad will be. We have a range of pads from coarse to ultra fine as well as wool pads and those specifically made for glass surfaces.

Foam polishing pads are most commonly used in the detailing industry. They come in many different grades, colours, and sizes to fit every type of machine polisher out there. A coarse or heavy cut pad is able to refine deep to medium scratches in the surface of your paintwork. A medium cut pad will work on medium scratches whilst a fine cut pad will work on fine scratches. A micro-cut or ultra-fine cut pad will work on super fine scratches as well as holograms on the surface. We recommend always starting with a medium or fine pad, you will then know whether a coarser pad is needed.

Finishing pads can also often be used to apply a sealant or a wax in order to speed up the finishing process. These are usually super soft and provide a high gloss on surfaces as a final step.

The Koch Chemie Polishing & Sealing Pad is made from extra fine sponge designed to economically and evenly apply sealing products such as Koch Chemie 1K Nano. The short height of 23mm creates low torsion forces whilst providing a high level of stability and excellent handling. The optimised reticulation (open cellular structure) and cell count provides a high level of abrasiveness and increases the lifespan of the pad. The milling edge enables increased flexibility, allowing them to move around contours more easily.

The Lake Country Blue Foam Finishing Pad is designed for use with sealants and glazes for final buffing and product removal. The soft absorbent foam will not scratch paintwork or absorb too much of the product. This increases polish and pad performance and efficiency. The special design of these pads means that the CCS pockets gradually release polish as needed by the operator. They also reduce surface tension which allows you to run the pad flat over the working surface and prevents pad skipping. The pockets reduce surface heat resulting in less friction generated heat.